Services

- CNC milling

- CNC turning

- OneCNC CAD / CAM

- Reverse engineering & 3D milling

- Design & manufacture

- Inspection

- Finishing & assembly

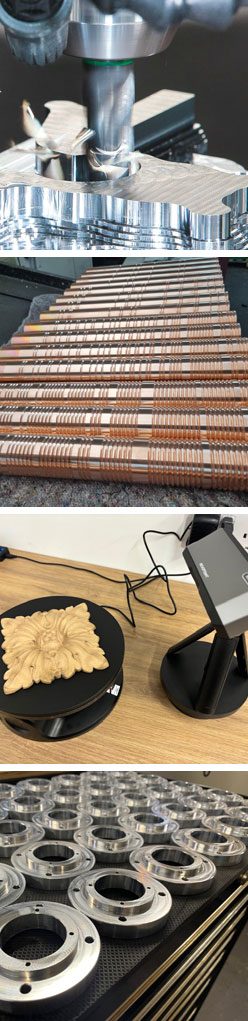

CNC Milling

AEP Precision Engineering have full CNC milling facilities, including 4th axis capability and we work in a wide range of plastics and metals, supplying all types of industry. We offer rapid prototyping right through to full production.

CNC Turning

AEP Precision Engineering

have full CNC turning facilities including a fully automated bar fed CNC

lathe and work with a wide range of plastics and metals, supplying all types

of industry. We offer rapid prototyping right through to full production.

OneCNC CAD / CAM

AEP Precision Engineering

uses OneCNC CAD / CAM (computer aided design / computer aided manufacturing)

XR9 technology to transform initial concept drawings and designs into

physical parts.

Reverse Engineering & 3D Milling

AEP Precision Engineering

have scanning facilities, using a Revopoint 3D scanner to create digital 3D

models to manufacture duplicate components using CAD / CAM software.

Design & Manufacture

AEP Precision Engineering

offer a full design and manufacturing service, from initial consultation

where concepts are designed using CAD / CAM technology, right through to

manufactured prototypes.

Inspection

AEP Precision Engineering

provide a full inspection service that is designed to meet our customer's

needs, including first part inspection, part batch inspection and full final

inspection.

Finishing & Assembly

AEP Precision Engineering

offer a full finishing and assembly service. This

includes all forms of finishing such as anodising, patination, powder

coating, helicoil insertion and assembly of components into finished

products.